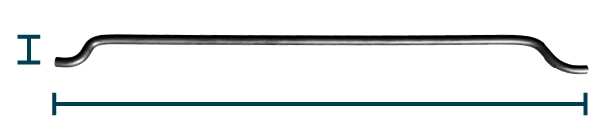

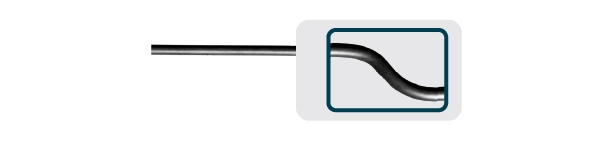

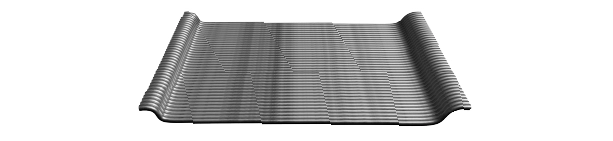

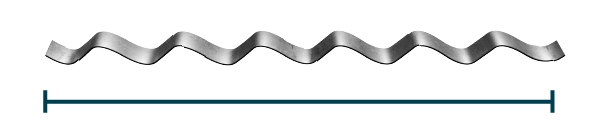

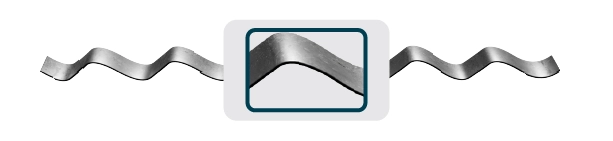

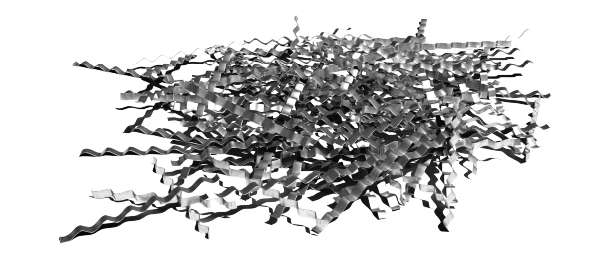

ENVIROMESH® has a range of steel fibres that are widely used in infrastructure projects. Our steel fibres are available in lengths from 38 mm to 50 mm and aspect ratios between 40 and 60. The fibres are manufactured either deformed or hook end and conform to ASTM A-820.

Steel fibres strengthen concrete by resisting tensile cracking. Concrete reinforced with steel fibres has more flexural strength than concrete reinforced with welded wire mesh. Steel fibres reinforce concrete isotropically, which enhances the concrete’s resistance to cracking, fragmentation, spalling and fatigue.

Steel fibres in concrete provide better impact resistance and dynamic loading. They make concrete more ductile and more resistant to bending. Using steel fibres as reinforcement reduces overall construction and maintenance cost, and faster construction time by eliminating the need for additional reinforcement.

Steel fibre reinforced concrete acts as a uniform material. In comparison to plain or conventionally reinforced concrete, the most noticeable differences are better ductility and post-crack performance. Using steel fibres means minimised need for materials and labour on the site. It also leads to reduction in product damage and wastage as fibres fully distribute through concrete.

An important advantage of replacing steel mesh with steel fibres, In sprayed concrete is minimal losses from rebound and no integrity loss from shadowing from mesh. Steel fibres can be used solely or in addition to the conventional steel mesh or rebar depending on applications, design and specifications

Your inquiry will be sent to the relevant department

If you are an existing customer / service provider / material supplier, please contact your respective ENVIROMESH representative in your region for a quicker response.

Traffic Systems Limited (TSL)

All enquiries for the UK, Ireland and Americas can be sent to our Australian HO. We are working on setting up our branches in London and New York.

Manufacturers and suppliers of fibres for concrete reinforcement.